June 13, 2023

The production process of heavy medium powder

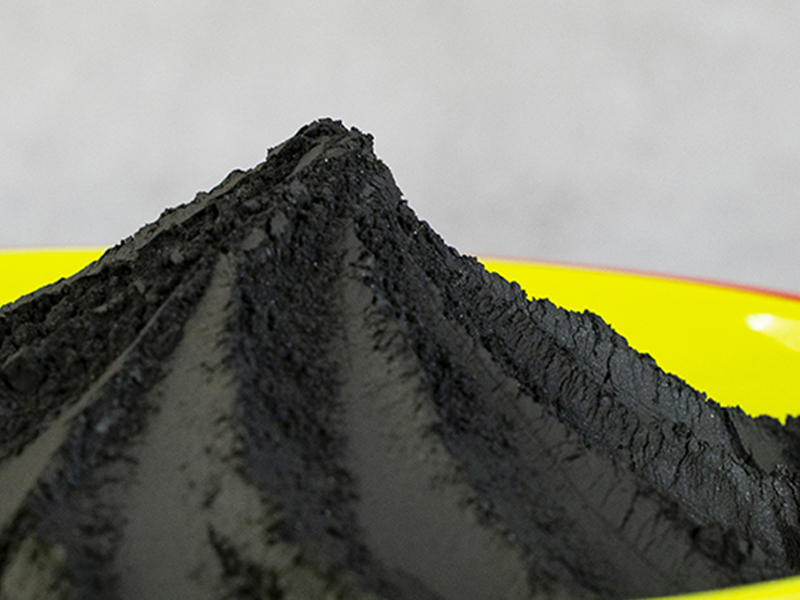

The production process of heavy medium powder

The production process of heavy medium powder

Heavy medium beneficiation process mainly includes ore preparation, medium preparation, ore separation, medium recovery, medium regeneration and other operations. Typical beneficiation process using ferrosilicon or magnetite heavy suspension as medium.

(1) Preparation of selected ore

Before heavy media beneficiation, the preparation of selected ore is mainly: crushing, screening, washing, dehydration and other operations. The washing and screening work can be done simultaneously on the screening machine by spraying water. The screening machine mainly uses linear vibrating screen and self-set center vibrating screen in our country. The washing water pressure is 100~125kPa, and the water consumption is 0.2~0.9m3/t ore. The fine content of the products on the screen should not exceed 0.2%~0.3%.

(2) Medium preparation

When this process uses block ferrosilicon or magnetite as the weight, it must be crushed in a special crusher and mill to achieve qualified particle size requirements. The operation process of crushing and grinding is basically the same as that of crushing and grinding raw ore in general concentrator. When the sprayed granular ferrosilicon or magnetite and pyrite concentrate is used as the weighting material, it is generally not necessary to re-grind, unless the particle size is coarser before re-grinding. The grinding weight is then magnetically separated (in addition to the removal of non-magnetic impurities) or concentrated (in the medium of sulfide ore, etc.), and then prepared into a certain concentration of suspension in the mixing tank for sorting applications.

(3) Ore sorting

This operation is the separation of light and heavy minerals in the separation equipment, and is the central link of heavy suspension beneficiation. In the production process, the most important thing is to stabilize the density of the sorting medium so that its fluctuation range does not exceed ±0.01. The stability of the suspension density is closely related to the ore preparation and the recovery and regeneration of the suspension. In order to find out whether the density of suspension meets the requirements in time, it should be measured regularly.

(4) Media out

The first stage sieve out the concentrated medium and directly return to the process for use; The second stage is washed with water on the screening machine to wash off the weight attached to the ore, the two stages of screening can also be carried out on the same screen, the front 25% to 30% of the length of the dense medium, and the back is washed with water. The screens used are linear vibrating screen, self-centered vibrating screen and resonance screen. The screen surface is mostly a slit screen, and the slit width is 2~3mm or smaller. I saw it in China * coal washing equipment trading network

(5) Medium regeneration

Generally, the concentrated medium mass out accounts for about 90% to 95% of the entire working medium mass, and the rest of the weighted substance adhering to the ore is washed into a dilute medium, which is heavily polluted. The process of purifying a dilute medium and increasing its high concentration is called regeneration of the medium. The regeneration method can be carried out by magnetic separation, flotation or gravity separation according to the different properties of the weight. The purified dilute suspension is then dehydrated and concentrated by hydrocyclone, tilting thickener and other equipment. The resulting purified suspension can then be mixed with the newly replenished accentuator, blended into the appropriate concentration and returned to the process for use

STAY IN THE LOOP

We look forward to being able to establish contact with you, if you have any questions about minerals need to consult, you can also contact us, our professional technical engineers will contact you within 24 hours!