Description

Species Introduction

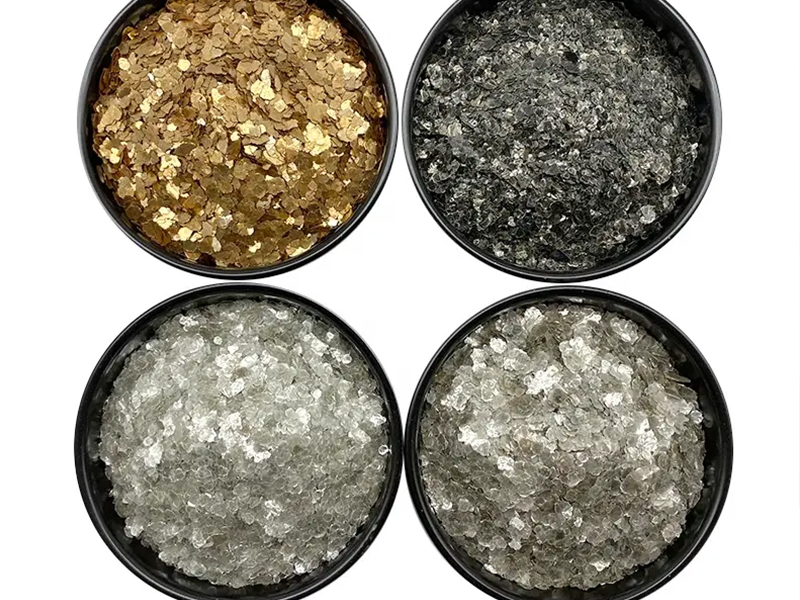

Mica is the general name of mica minerals, is potassium, aluminum, magnesium, iron, lithium and other metals of aluminum silicate, are layered structure, monoclinic crystal system. Crystals are pseudohexagonal or platelike, occasionally columnar. The lamellar cleavage is very complete, glassy, and the flakes are elastic. The refractive index of mica increases with the increase of iron content, ranging from low orthotropic to medium orthotropic. Varietals without iron, colorless in flakes, the higher the iron content, the darker the color, and increased polychromism and absorption.

Mica ore mainly includes biotite, gold mica, Muscovite, lepidolite, sericite, green mica, iron lepidolite, etc. Placer gold stone is a mixed mineral of mica and quartz. Muscovite and metallovite are used most in industry. Lepidolite is an important mineral raw material for extracting lithium.

Mica mines were widespread in Asia, Africa, and the Americas, but rarely in Europe, where the value of mica was very high until the 19th century, and prices fell rapidly as colonists mined it in Africa and South America.

Mineral characteristics

The main minerals of mica pegmatite ore are microclinite, feldspar, quartz and Muscovite, while the secondary minerals are biotite, ferruginite, tourmaline, apatite, beryl and ilmenite. Minerals such as apatite, tremolite, diopside, calcite, carbonate rocks and microplagioclase often occur in the veins of gold mica deposits. Muscovite deposits generally account for 50~70%, potassium feldspar and quartz account for about 10%, and trace minerals are magnetite and limonite.

Mica is an aluminosilicate mineral with continuous layered silico-oxygen tetrahedron structure. It is divided into three subgroups: Muscovite, biotite and lelithium. Muscovite includes Muscovite and its subspecies (sericite) and less common sodimica; Biotite includes gold mica, biotite, iron biotite and manganese biotite; Lepidolite is a small scale of various mica rich in lithium oxide. Muscovite and metallovite are commonly used in industry, especially in electrical industry.

The chemical formula of mica is KAl2 [AlSi3O10] [OH] 2, in which SiO245.2%, Al2O338.5%, K2O11.8%, H2O4.5%, and a small amount of Na, Ca, Mg, Ti, Cr, Mn, Fe and F are contained. The chemical formula of metallomica is KMg3 [AlSi3O10] [F, OH] 2, in which K2O7~10.3%, MgO 21.4~29.4%, Al2O3 10.8~17%, SiO2 38.7~45%, H2O 0.3~4.5%, containing a small amount of Fe, Ti, Mn, Na and F. Mica is mostly monoclinic crystal system, in the form of laminated or booklike crystal shape, complete development for six crystal surface rhomboidal or hexagonal, sometimes form false hexagonal columnar crystal.

Mica has perfect cleavage and can be peeled. In theory, Muscovite can be peeled into about 10 pieces, and gold mica can be peeled into about 5 or 10 pieces. The hidden cleavage of mica crystal is the image hitting and pressing. Muscovite flakes are generally colorless and transparent, but often dyed green, brown, yellow and pink tones; Glass luster, cleavage surface is pearl luster. Gold mica is usually yellow, brown, dark brown, or black; Glass luster, cleavage surface is pearl or semi-metallic luster. The transparency of Muscovite is 71.7~87.5%, and that of gold mica is 0~25.2%. The Mohs hardness of Muscovite is 2~2.5, and that of gold mica is 2.78~2.85. The elastic coefficients of Muscovite are (1475.9~2092.7×106Pa(15050~21340kg/cm2) and (1394.5-1874.05)×106Pa(14220~19110kg/cm2). [3]

Main use

| 1.Industrial use |

| Biotite industry mainly uses its insulation and heat resistance, as well as acid resistance, alkali resistance, pressure resistance and stripping properties, used as electrical equipment and electrical equipment insulation materials; Secondly, it is used to manufacture steam boilers, furnace Windows of smelting furnaces and mechanical parts. Mica and mica powder can be processed into mica paper, but also can replace mica sheet to produce a variety of inexpensive, uniform thickness insulation materials. Muscovite is the most widely used in industry, followed by metallovite. It is widely used in building materials industry, fire industry, fire extinguishing agent, welding rod, plastic, electrical insulation, paper, asphalt paper, rubber, pearlitic pigment and other chemical industry. Superfine mica powder used as functional filler for plastics, coatings, paints, rubber, etc., can improve its mechanical strength, toughness, adhesion, aging resistance and corrosion resistance. In addition to very high electrical insulation, acid and alkali corrosion resistance, elasticity, toughness and sliding, heat resistance and sound insulation, thermal expansion coefficient of small properties, and the first to introduce the smooth surface of the two sheet body, diameter thickness ratio, regular shape, strong adhesion and other characteristics. |

| 2.Mica medicinal |

| Mica, sweet taste, flat nature. Injured by wind evil and cold fever, like the body sitting on a boat, dizzy, with build up to remove wind evil, enrich the five viscera, increase fertility, make the eyes bright, long clothing body light dexterity, prolong life. Also known as cloud beads, Yunhua, Yunying, cloud liquid, cloud sand, phosphorus stone, produced deep in the mountains. |

Process Technology

| Beneficiation of mica ore is a process of enrichment of raw mica. Raw mica refers to the mica crystal of any thickness with contour area greater than or equal to 4cm2 in raw ore. The amount of raw mica content in raw ore is called raw mica ore rate, usually expressed by the weight of raw mica contained per unit of ore volume (kg/m3). The ratio of the total weight of raw mica in the concentrate obtained from beneficiation to the total weight of raw mica in the raw ore is called the recovery rate. |

| In industry, mica natural crystal is directly used to process into required products. The larger the mica crystal without defects is, the higher its economic value is. Therefore, in the process of mica ore dressing, it is necessary to protect mica natural crystal from destruction as much as possible. |

| The beneficiation of sheet mica with crystal contour area greater than 4cm is mainly carried out according to the difference in shape and friction coefficient between mica crystal and gangue. The commonly used methods include hand selection, friction selection and shape selection. For broken mica whose crystal contour area is less than 4cm, the separation is mainly carried out according to the difference between the physical and chemical properties of the mica and gangue surface, and the flotation method is adopted. |

(1) Beneficiation method and process of sheet mica

| A.Hand Selection |

| Workers in the mining face or ore heap at the mouth of the mine, has been the separation of single mica; The appendages of mica and gangue are broken with a hammer and the mica in them is selected. |

| B.Friction Selection |

| According to the difference of sliding friction coefficient between lamellar mica crystal and circular gangue, mica crystal and gangue are separated. One of the equipment used is the inclined plate sorter. The machine is composed of a group of metal inclined plate, each inclined plate length 1350mm, width 1000mm, the Angle of the next inclined plate is greater than the Angle of a inclined plate. The lower end of each inclined plate has a slit for collecting mica crystals, the width of which decreases in the order of the inclined plate. There is a triangular weir plate at the leading edge of the gap. In the process of sorting, large gangue tumbled to the pile; Mica and smaller gangue blocks are blocked by weir plate, and a inclined plate falls through the gap. The process is repeated in turn on the inclined plate to gradually separate the mica from the gangue. The process and equipment of friction beneficiation are not perfect, so it has not been widely used in the beneficiation of mica ore. |

| C. Shape Selecction |

| According to the different shape of mica crystal and gangue, the ability to pass through the sieve seam and sieve hole is different in screening, so that mica and gangue are separated. Selection, the use of a more than two layers of different screen structure of the screen, generally the first layer of screen mesh bar shape; The second screen is square. When the raw ore enters the screen surface, due to vibration or rolling, flake mica and small gangue can be leaked from the strip sieve seam to the second screen surface; Because the second layer is a sieve, it can screen gangue leaving flake mica. Shape beneficiation has been widely used in mica mines because of its advantages such as simple flow, less equipment, high productivity and good separation effect. |

Mica crushing process

| A. Flotation |

| According to the surface physical and chemical properties of mica and gangue different sorting. After crushing and grinding, the mica monomer is dissociated. Under the action of chemicals, the mica becomes foam product and is separated from gangue. Mica flotation can be carried out in acidic or alkaline pulp, long carbon chain amines cations and fatty acid anions are the collectors of mica. Mica concentrate can be obtained only after three stages of roughing and selection in mica flotation process. Therefore, flotation of mica ore is used to recover mica and fine mica from pegmatite and mica schist up to 14 mesh. In our country, mica flotation is not used. |

| B. Air Aeparation |

| Mica air separation is realized by special equipment. The process is generally: crushing, screening, classification, air separation. After the ore is broken, mica basically forms a thin flake, while gangue minerals such as feldspar and quartz are massive particles. Therefore, the selected materials are pre-divided into narrower particle sizes by multistage classification. According to the difference of their suspension velocity in the air stream, special air separation equipment is used for sorting. Air separation method is suitable for water shortage areas, has been used in actual production. |

Process characteristic

| Physical property |

| The physical properties of mica are mainly determined by the size of mica crystal, cleavage and hardness of mica and mica color transparency and elasticity. | |

| Industrial mica is laminated or booklike crystal shape, crystal size, thickness from a few millimeters to dozens of centimeters, generally as long as the effective area of the crystal is greater than or equal to 4cm2, it has direct use value. Of course, the larger the crystal area, the higher the value. The stripping property of mica is determined by the cleavage and hardness of mica. The unique crystal structure of mica makes it have a group of extremely complete underside cleavage, which becomes an important property of industrial mica technology processing stripping. In theory, Muscovite can be peeled to about 10, and metallomica can be peeled to about 5-10. Therefore, Muscovite and metallomica can be stripped into flat sheets of any thickness according to industrial requirements, in order to meet the requirements of electrical and electronic industries for mica. The hardness of mica is low, including 2-2.5 Muscovite, 2.37 Muscovite and 2.78-2.85 metallovite. The harder mica is, the harder it is to strip. The stripping properties of Muscovite and magnesia silicomite are better than those of gold mica. The color characteristics of mica are often used to characterize the insulation properties of mica. The best industrial mica is pale Muscovite, followed by gold mica, and biotite has the worst insulation properties. The elastic coefficient of Muscovite is 15346-21760bar, and that of goldmica is 14500-19480bar. When mica is used as insulation material in industry, there are strict requirements on its elasticity. | |

Electrical performance

| The insulation property of mica is the most important factor to determine its industrial use value. The insulation property of mica is determined by the electrical property of mica. The electrical property of mica is determined by testing the breakdown voltage and breakdown strength. According to the test results of mica in various mining areas, when the thickness of mica is 0.015mm, the average breakdown voltage is 2.0-5.7kV and the breakdown strength is 133-407kV/mm. |

Heat Resistance

| The elasticity and surface properties of some Muscovite in our country are unchanged when it is heated at 100~600℃. After 700~800℃, dewatering, mechanical, electrical properties have changed, elasticity loss, become brittle; At 1050℃, the structure fails. At about 700℃, the electrical performance of gold mica is better than that of white mica. (4) Mechanical strength and density items white cloud mother gold cloud mother mechanical tensile strength 166700 ~353039(1700~3600) 156906 ~ 205939(1600 ~2100) strength compressive strength 813951~1225831(8300 ~ 12500) 294199 ~ 588399(3000 ~ 6000) kPa shear strength 210843 ~ 296063(2150 ~ 3019) 82768 ~ 135332(844 ~ 1380) density, g/cm 3 2.7 ~ 2.88 2.7 ~ 2.9 Note: The units in brackets are kg/cm 2. [3] |

Reviews

There are no reviews yet.