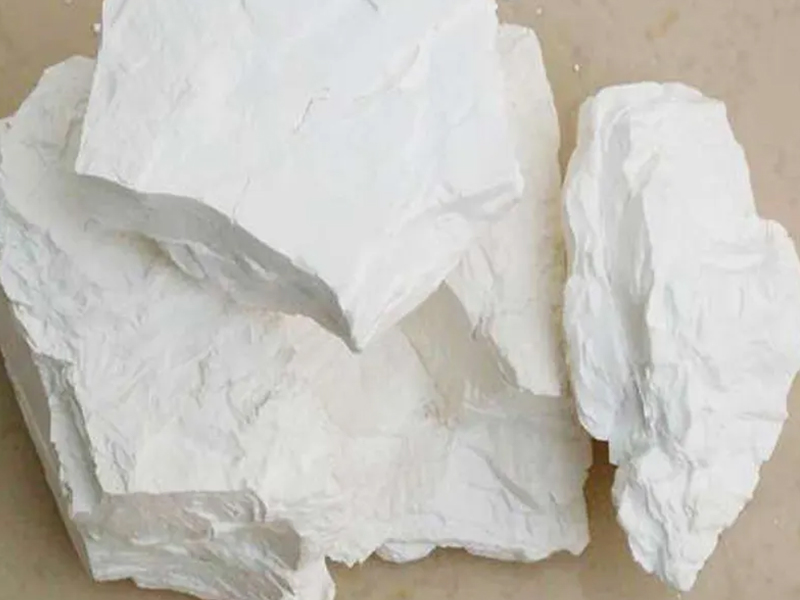

High whiteness Calcined Kaolin used in ceramic paper coating rubber

Kaolin is a kind of non-metallic mineral. It is a kind of clay and clayrock mainly composed of kaolinite clay minerals. Because of its white and fine, also known as dolomite. It is named after Gaoling Village in Jingdezhen, Jiangxi Province.

Its pure kaolin is white, delicate, soft soil, with good plasticity and fire resistance and other physical and chemical properties. Its mineral composition is mainly composed of kaolinite, helolite, hydromica, illite, montmorillonite, quartz, feldspar and other minerals. Kaolin is widely used, mainly used in paper making, ceramics and refractory materials, followed by paint, rubber filler, enamel glaze and white cement raw materials, a small amount of plastic, paint, pigment, grinding wheel, pencil, daily cosmetics, soap, pesticides, medicine, textile, petroleum, chemical, building materials, national defense and other industrial sectors.

| |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Please contact us for detailed product information and product quotation, the pictures shown on the website are for reference only.

Description

Constituent

Kaolinite minerals are composed of kaolinite cluster minerals such as kaolinite, crescite, pearlite and helolite, and the main mineral component is kaolinite.

The crystal chemical formula of kaolinite is 2SiO2●Al2O3●2H2O, and its theoretical chemical composition is 46.54% SiO2, 39.5% Al2O3 and 13.96% H2O. Kaolin minerals belong to the 1:1 type of phyllosilicates, crystals are mainly composed of silico-oxygen tetrahedron and alumino-oxygen octahedron, silico-oxygen tetrahedron in the way of sharing the top Angle along the two-dimensional direction to form a hexagonal arrangement of grid layers, each silico-oxygen tetrahedron not common apex oxygen are oriented to one side; The unit layer of 1:1 is composed of the silico-oxygen tetrahedral layer and the alumino-oxygen octahedral layer, which share the apex oxygen of the silico-oxygen tetrahedral layer.

Physicochemical property

Properties: no luster, pure and delicate white, such as impurities can be with gray, yellow, brown and other colors. Depending on the origin of different appearance can be loose soil block and dense state rock block.

Density: 2.54-2.60 g/cm3.

Melting point: about 1785℃.

Plastic, wet soil can be shaped into various shapes without breaking, and can remain unchanged for a long time.

Genesis of deposit

Kaolin is a common and very important clay mineral in nature. It is formed by weathering of feldspar or other silicate minerals in igneous and metamorphic rocks in acidic media lacking alkali metals and alkaline earth metals.

Soil classification

The minerals contained in kaolin in nature are mainly divided into clay minerals and non-clay minerals. The clay minerals mainly contain kaolinite minerals and a small amount of montmorillonite, mica and chlorite. Non-clay minerals mainly include feldspar, quartz and hydrates, and some iron minerals such as hematite, siderite, limonite, titanium minerals such as rutile and organic matter such as plant fiber. The properties of kaolin are mainly determined by clay minerals.

Genetic classification

On the basis of the formation of kaolin deposits, according to the differences of ore-forming geology, geographical conditions, deposit scale, morphology and occurrence characteristics of ore bodies, ore material components and other aspects reflected in different mineralization processes, the Geological Exploration Standard of Kaolin deposits in China is divided into three types and six sub-types.

1. Weathering type: it is divided into weathering residual subtype and weathering eluvial subtype;

2. Hydrothermal alteration type: it is divided into hydrothermal alteration subtype and modern hydrothermal alteration subtype;

3. Sedimentary type: It is divided into sedimentary and depositional weathering subtypes and kaolinite claystone subtypes in coal-bearing strata.

Industrial type

It can be divided into three types according to its texture, plasticity and sandy quality fraction:

1.Hard kaolin: hard, no plasticity, after grinding fine plasticity.

2.Soft kaolin: soft, plasticity is strong, sandy quality fraction <50%;

3.Sandy kaolin: soft quality, plasticity is weak, sandy quality fraction<50%.

Process characteristic

| Whiteness brightness | |||

| Whiteness is one of the main parameters of kaolin technology performance, and high purity kaolin is white. Kaolin whiteness is divided into natural whiteness and calcined whiteness. For ceramic raw materials, the calcined whiteness is more important, the higher the calcined whiteness, the better the quality. The process of ceramics stipulates that drying at 105℃ is the classification standard of natural whiteness and calcination at 1300℃ is the classification standard of natural whiteness. Whiteness can be measured by a whiteness meter. The whiteness meter is measured against 3800 — 7000Å (ie, angstrom, 1 angstrom =0.1 nm) wavelength light reflectance device. In the whiteness meter, the reflectance of the sample to be measured is compared with that of the standard sample (such as BaSO4, MgO, etc.), that is, the whiteness value (for example, 90 is equivalent to 90% of the reflectance of the standard sample). Brightness is a process property similar to whiteness, equivalent to 4570Å (angstrom) whiteness under wavelength light exposure. The color of kaolin is mainly related to the metal oxide or organic matter it contains. Generally containing Fe2O3 rose red, brown yellow; Fe2+ is light blue, light green; MnO2 is light brown. Organic matter is light yellow, gray, green, black and other colors. The presence of these impurities reduces the natural whiteness of kaolin, among which iron and titanium minerals will also affect the calcined whiteness, causing the porcelain to appear stains or scars. | |||

Particle size distribution

Particle size distribution refers to the proportion (expressed in percentage) of particles in natural kaolin within a given continuous range of different particle sizes (expressed in millimetre or micron sieve mesh). The particle size distribution of kaolin is of great significance to the beneficiability and technological application of ore. Its particle size has great influence on its plasticity, mud viscosity, ion exchange capacity, molding performance, drying performance and sintering performance. All kaolin ore needs technical processing, and whether it is easy to process to the required fineness has become one of the criteria to evaluate the quality of ore. Various industrial departments have specific requirements of granularity and fineness for different uses of kaolin. Such as the United States for the use of kaolin coating requirements less than 2μm content of 90-95%, papermaking filler less than 2μm account for 78-80%.

Associativity

Binding property refers to kaolin combined with non-plastic raw materials to form plastic mud and has a certain drying strength. The binding capacity was measured by adding standard quartz sand to kaolin (70% of its mass composition is 0.25-0.15 grain size and 30% is 0.15-0.09 mm grain size). The highest sand content and the flexural strength after drying can be used to judge the level of kaolin. The more sand mixed, the stronger the binding ability of kaolin. Generally, kaolin with strong plasticity has strong bonding ability.

Viscosity

Viscosity refers to a characteristic inside a fluid that impedes its relative flow due to internal friction. Its magnitude is expressed in terms of viscosity (internal friction acting on 1 unit area) and is expressed in Pa·s. The measurement of viscosity, generally using a rotary viscometer, is measured by the rotational speed in kaolin mud with 70% solid content. In the production process, viscosity is of great significance. It is not only an important parameter in the ceramic industry, but also has great influence on the paper industry. According to the data, the viscosity of kaolin coating abroad is required to be about 0.5Pa·s in low speed coating and less than 1.5Pa·s in high speed coating.

Thixotropy refers to the behavior of mud that has been gelled and no longer flowing and becomes a fluid after being pressed and then gradually thickens into its original state after resting. Its size was expressed by thickening coefficient and measured by outflow viscometer and capillary viscometer.

Viscosity and thixotropy are related to mineral composition, particle size and cation type in mud. In general, montmorillonite content is high, fine particles, exchangeability cations are mainly sodium, and its viscosity and thickness coefficient are high. Therefore, it is commonly used to add clay with strong plasticity and improve the fineness to improve its viscosity and thixotropy, and reduce it by increasing dilute electrolyte and water.

Drying property

| Sinter property Sinter property refers to the performance of material filling grain gap spontaneously and densification when the formed solid powder kaolin billet is heated close to its melting point (generally more than 1000℃). The state when the porosity drops to the lowest value and the density reaches the maximum is called sintering state, and the corresponding temperature is called sintering temperature. When heating continues, the liquid phase in the sample continues to increase, and the sample begins to deform. At this time, the temperature is called the conversion temperature. The interval between sintering temperature and conversion temperature is called sintering range. Sintering temperature and sintering range are important parameters for determining billet formulation and kiln type in ceramic industry. Low sintering temperature and wide sintering range (100-150 ℃) are suitable for the test material. The sintering temperature and sintering range can be controlled by mixing fusible materials and proportioning kaolin of different types. | |||

| Firing shrinkage Firing shrinkage refers to a series of physical and chemical changes (dehydration, decomposition, generation of mullite, melting of fusible impurities into glass phase filling the space between particles, etc.) occurring in the firing process of the dried kaolin billet, which leads to the shrinkage of products, which can also be divided into linear shrinkage and bulk shrinkage. As with dry shrinkage, burning shrinkage is too large, easy to cause the body cracking. In addition, when roasting, if there is a large amount of quartz mixed in the billet, it will undergo crystal transformation (tripartite → hexagonal), so that its volume expansion, but also produce reverse contraction. | |||

| Fire resistance Fire resistance refers to the ability of kaolin to resist high temperature without melting. The temperature at which softening occurs and melting begins under high temperature operation is called refractoriness. It can be measured directly by standard temperature cone or high temperature microscope, or by M.A. Bezbellodov empirical formula to calculate. Refractories t (℃) =[360+Al2O3-R2O]/0.228 | |||

| levitation Suspension and dispersion refers to the property that kaolin dispersed in water is difficult to precipitate. Also known as reverse flocculation. Generally, the finer the particle size, the better the suspension. Kaolin used in enamel industry requires good suspension. Generally, the suspension performance is determined by the settling velocity of the samples dispersed in water after a certain period of time. | |||

| Selectable The selectibility refers to the performance that kaolin ore is hand-selected, machined and chemically treated to remove harmful impurities and make the quality meet the industrial requirements. The selectibility of kaolin depends on the mineral composition, occurrence state and particle size of harmful impurities. Quartz, feldspar, mica, iron, titanium minerals are harmful impurities. Kaolin mineral processing mainly includes sand removal, iron removal, sulfur removal and other items. | |||

| Adsorbability Kaolin has the ability to absorb various ions and impurities from the surrounding medium and has weak ion exchange property in solution. These properties are mainly determined by the main mineral composition of kaolin, as shown in Table 8. | |||

| Chemical stability Kaolin has strong acid resistance, but its alkali resistance is poor. This property can be used to synthesize molecular sieves. | |||

| Processing mode As far as the current processing methods of kaolin are concerned, there are two ways: mechanical crushing and air crushing. And mechanical grinding is generally crushed to 300-1000 mesh, but its grinding processing is mechanical, so there is an increase in iron content and other impurities in the pulverized fine powder, for the application of high purity industry, there are defects; Air crushing due to the collision and shear between materials and materials, no crushing medium involved, thus effectively ensure the purity of the material, so as to meet the requirements of high purity industry application efficiency, at the same time, the air crushing fineness of up to 5000 mesh (fineness range can be adjusted 1000 mesh -5000 mesh). | |||

| Separation method (1) In order to separate quartz, feldspar, mica, iron minerals, titanium minerals and other non-clay minerals and organic matter in kaolin, and produce kaolin products that can meet the needs of various industrial fields, in addition to the purification of kaolin by gravity separation, flotation, magnetic separation, etc. Sometimes, kaolin is treated by chemical bleaching, ultrafine stripping, calcination, surface modification and other deep processing methods. The beneficiation processing of kaolin can be divided into dry method and wet method. </p><p> (1) The dry method is generally to break the mined raw ore to about 25mm through the crusher and feed it into the cage crusher to reduce the particle size to about 6mm. The crushed ore is further refined by an air-blown Raymond mill equipped with a centrifuge and a cyclone. This process can remove most of the sand, and is suitable for processing those ores with high raw ore whiteness, low sand content and suitable particle size distribution. Dry processing has low production cost, and the products are usually used as low price fillers in rubber, plastics and paper industry. | |||

| (2) Wet processing process will generally be broken raw ore, after ramming, sand removal, cyclone classification, stripping, centrifuge classification, magnetic separation (or bleaching), concentration, pressure filtration, drying, so that the product can be used for ceramic or paper coating. If the preparation of packing grade or papermaking coating grade kaolin needs to increase the calcining process, that is, raw ore grinding, ramming, cyclone classification, stripping, centrifugal classification, concentration, pressure filtration, internal steam drying, calcining, depolymerization, etc. | |||

| (3) Calcination Calcination is a widely used method for the production of special kaolin products. It has 4 calcination temperature ranges: 500 ~ 700℃, 925℃, 1000℃, 1400℃. Calcined at different temperatures, the product range of application is different, only hydroxyl removed calcined kaolin used as cable plastic and rubber sealing ring filler; Kaolin calcined at 1000℃ can be used as paper filler instead of Tio2; After 1300 ~ 1525℃ calcined kaolin can be used as the filler of refractory products, optical glass crucible lining, etc. | |||

| (4) Peeling method In order to prepare coating grade kaolin products, it is necessary to peel thick laminated kaolin into thin slices. The peeling methods include wet grinding, extrusion and chemical soaking. (1) Wet grinding method is used to prepare kaolin into pulp with a solid volume of about 40%. After adding dispersant, the grinding medium (such as quartz sand, porcelain beads, glass beads, nylon polyethylene beads, etc.) is added to the grinding machine. After grinding for a certain time, it is screened and then obtained by precipitation classification. ② The extrusion method will send the kaolin slurry to the high pressure homogenizer, pressurize the high pressure homogenizer to 20 ~ 35Mpa, and then spray out from the nozzle, because of the sudden reduction of pressure, the kaolin crystal stack “loose”. The slurry sprayed at high speed is sprayed to the impeller, and the direction of movement is suddenly changed, so that the loose crystal layers are stripped. ③ Chemical soaking method soaked kaolin powder with urea saturated solution, heated to 30 ~ 80℃, and then added a small amount of dispersant, so that kaolin fully dispersed, high-speed stirring, so that the crystal layer stripping. Benzidine and acetamide can also be used instead of urea. The neutral aqueous solution of AlCl3 was mixed with Na2SiO3 in the ratio of 1∶0.75 to 1∶5 to produce precipitation. When dried at 110℃, Al2O3·2SiO2·2H2O is obtained. | |||

| (5) The kaolin is ground fine, washed to remove sand, treated with inorganic acid, washed to nearly neutral, and dehydrated above 30 ℃ |

Industrial use

Kaolin has become a paper, ceramics, rubber, chemical, paint, medicine and national defense dozens of industries necessary mineral raw materials.

Ceramic industry is the earliest application of kaolin, large amount of industry. The general dosage is 20% ~ 30% of the formula. The role of kaolin in ceramics is to introduce Al2O3, which is conducive to the generation of mullite, improve its chemical stability and sintering strength. In the firing process, kaolin decomposition generates mullite, forming the main frame of the strength of the billet, which can prevent the deformation of the products, make the firing temperature wider, but also make the billet has a certain whiteness. At the same time, kaolin has a certain plasticity, cohesiveness, suspension and bonding ability, giving porcelain mud, porcelain glaze good formability, so that ceramic mud billet is conducive to car billet and grouting, easy to form. If used in wire, can increase the insulation, reduce its dielectric loss.

Ceramics not only have strict requirements on kaolin plasticity, binding, drying shrinkage, drying strength, sintering shrinkage, sintering properties, refractoriness and post-burning whiteness, but also involve chemical properties, especially the presence of iron, titanium, copper, chromium, manganese and other color elements, so that the whiteness after burning is reduced and spots are produced.

Generally, the finer the granularity of kaolin is required, so that the porcelain mud has good plasticity and drying strength. However, for the casting process requiring fast casting, accelerating the grouting speed and dehydration speed, it is necessary to increase the granularity of the ingredients. In addition, the difference in the degree of kaolinite crystallization in kaolinite will also significantly affect the technological performance of porcelain billet. If the degree of crystallization is good, the plasticity and bonding ability will be low, the drying will be reduced, the sintering temperature will be high, and the impurity content will be reduced. On the contrary, its plasticity is high, dry shrinkage is large, sintering temperature is low, the corresponding impurity content is high.

Additional information

| Weight | 24 kg |

|---|---|

| Dimensions | 12 × 48 × 62 cm |

Reviews

There are no reviews yet.