June 13, 2023

The physical properties of heavy medium powder for coal washing and the process of coal preparation with heavy medium

The physical properties of heavy medium powder for coal washing and the process of coal preparation with heavy medium

The physical properties of heavy medium powder for coal washing and the process of coal preparation with heavy medium

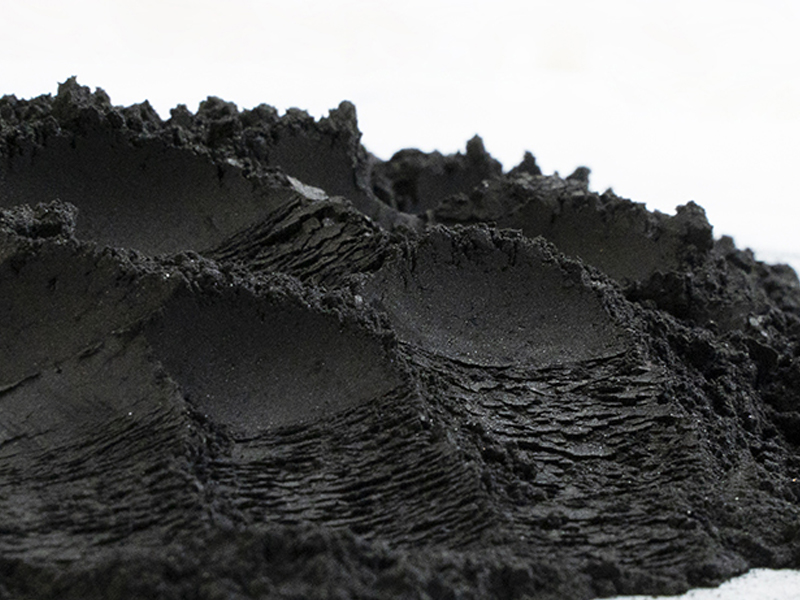

1. The heavy medium used by the coal washing machine has two categories of heavy liquid and heavy suspension. Organic solution and inorganic salt water are heavy liquids, they are stable media, placed for a long time to maintain their physical properties. Suspension is a mixture of solid particles and water, the particles sink after standing, so that the density of the suspension is inconsistent, and it is an unstable medium. Heavy liquid price is high, not easy to recover, most of them are toxic or corrosive, so they are not used in industry, only in the laboratory for coal float and sink test. At present, suspension of heavy medium powder and water is widely used as heavy medium powder for coal preparation at home and abroad. The suspension can be formulated to the required density and is easy to purify and recover the medium powder.

The main advantages of heavy medium coal washing machine for coal preparation are: the separation efficiency is higher than other coal preparation methods; The selected particle size range is wide, the inlet particle limit of the separator is 1000 to 6000, the cyclone is 80 to 150, and the media powder generation control is easy to automate. The disadvantages of heavy medium powder coal preparation are: the process is complicated and the production cost of medium powder is high; Equipment wear fast, large maintenance.

Coal preparation with heavy medium powder for coal washing is widely used. It can replace the hand-picked gangue, not only the sorting effect is good, the productivity is high, the medium powder and the heavy manual labor is liberated. Coal washing machine for difficult and extremely difficult coal separation, using full heavy medium separation or partial heavy medium powder separation process, can improve the yield of clean coal. The heavy medium cyclone used in coal washing machine can improve the yield and quality of clean coal. At present, the capacity of heavy medium coal washing machine in China is second only to jigging coal.

1. Raw coal preparation process

After the raw coal is classified by 50mm, +50mm lump coal is selected by inspection hand, wood blocks, wood chips, silk fabrics and other debris are picked, iron is removed by removing iron, broken to less than 50mm, and -50mm raw coal is added.

2. Sorting process

50-0mm raw coal to no pressure three products are separated by heavy mesocyclone, the bottom flow is directly used as gangue product after dehydration, and the intermediate product is directly used as medium coal after dehydration. The overflow is used as clean coal product after dehydration. Part of the qualified medium under the arc screen of clean coal deintermediation is divided into the coal slime qualified medium barrel, and the other part is returned to the raw coal qualified medium barrel. The slime qualified medium enters the slime heavy medium cyclone separation, and its overflow enters the magnetic separation of the refined coal magnetic separator. The concentrate passes through the diversion, part of it returns to the slime qualified medium bucket to adjust the separation density of the slime heavy medium cyclone, and the other part goes to the raw coal qualified medium bucket, and the tailings to the pulverized coal tailings bucket. Slime heavy medium cyclone bottom flow to middling waste separator magnetic separation. The qualified medium under the sifting of fine, medium and dirt is returned to the qualified medium barrel of raw coal, the dilute medium under the sifting is transferred to the magnetic separation of the respective magnetic separator, and the concentrate is returned to the qualified medium barrel of raw coal.

The tailings from clean coal magnetic separation to pulverized coal magnetic separation tailings bucket, and the tailings from middling waste magnetic separation to middling waste magnetic tail bucket, enter their respective crude coal slime recovery systems.

3. Slime water process

The tailings of the magnetic separation of pulverized coal are first graded by the hydraulic classification cyclone, and the bottom flow enters the curved screen for dewatering and desliming. The material on the screen is dehydrated by the high-frequency screen, and the refined coal products are added into the pulverized coal centrifuge for dewatering. The overflow, curved screen water, high-frequency screen water and centrifugal liquid are added to the flotation system.

The tailings from the magnetic separation of middling gangue are first graded by the hydraulic classification cyclone, and the bottom flow enters the arc screen for dewatering and desliming. After the material on the screen is dehydrated by the high-frequency screen, the tailings enter the medium coal slime centrifuge for dewatering and then mix the medium coal products. The overflow, arc screen water, high-frequency screen water and centrifugal liquid go to the tail coal concentrator.

STAY IN THE LOOP

We look forward to being able to establish contact with you, if you have any questions about minerals need to consult, you can also contact us, our professional technical engineers will contact you within 24 hours!